What is NACE MR0175/ISO 15156 for Steel Pipe?

-LongMa produce API 5L PSL2 line pipes with NACE MR 0175/ISO15156.

What is NACE?

In pipeline systems, we often encounter materials that meet NACE MR0175/ISO 15156 standards for pipes and fittings. Do you know the major differences between NACE carbon steel pipes and normal carbon steel pipes? Also, what is the cost difference for NACE materials?

NACE, or The National Association of Corrosion Engineers, was established in 1943 by 11 pipeline industry engineers with expertise in anti-corrosion. Its mission is to disseminate knowledge of anti-corrosion and improve corrosion prevention skills. NACE standards include MR0175, which outlines material requirements for oil and gas production and equipment that contain H2S.

NACE pipe is commonly used in gas and oil transportation that contains H2S.

The NACE MR0175 standard specification can be found here.

NACE MR0175/ISO 15156 provides guidelines for selecting qualified steel materials for use in equipment used in oil and gas production, as well as in natural gas sweetening plants operating in H2S-containing environments. The standard aims to prevent equipment failure, which could pose a risk to human health and safety, and cause environmental damage.

In the US, ISO 15156 recognises it as a federal standard for materials used in H2S-containing environments in the petroleum and natural gas industries.

How to select NACE MR0175 material?

When selecting or qualifying steel materials for use in H2S-containing environments in oil and gas production, it is important to note that materials selected or qualified using NACE MR0175/ISO 15156 are resistant to cracking in defined conditions, but may not be immune under all service conditions.

Therefore, it is important to follow the instructions for selecting qualified materials, including carbon and low-alloy steels, corrosion-resistant alloy steels, and other alloy materials that are resistant to H2S-containing environments. Meanwhile, the standard is also suitable for API, ASTM, ASME, and ANSI, among others.

In some cases, NACE pipe is also equivalent to sour service pipe, which is applied in H2S environments.

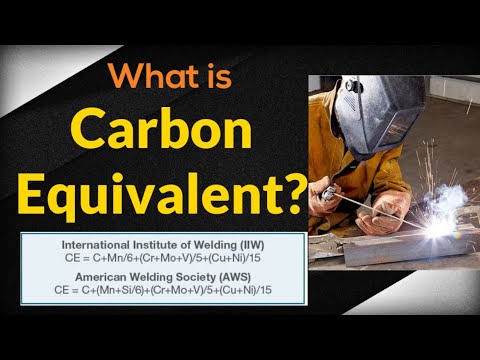

NACE Test Methods

For sour service steel pipes, plates, and fittings, there are two commonly referenced test methods in NACE standards: Hydrogen Induced Cracking (HIC) and Sulfide Stress Cracking (SSC).

The HIC test is a mandatory requirement for NACE pipes and fittings. However, if there is a certificate proving that the raw material used for manufacturing the pipes or fittings complies with NACE MR0175, then there is no need to conduct this test again.

The SSC test is a long-duration experiment conducted specifically on alloy steel. The test material is subjected to a corrosive environment while a constant pulling force is applied, simulating both working stress and internal forces. The combined effects of corrosion and force may cause brittle rupture, also known as SSC cracking.

This type of corrosion is considered one of the most detrimental. The rapid propagation of cracks caused by stress corrosion cracking (SSC) poses a significant risk to safety and can lead to catastrophic failures in various structures, including bridges, airplanes, and boiler tanks. These incidents can result in severe losses in terms of human lives and property damage. SSC accidents have been observed in power stations, ships, boiler tanks, and the petroleum industry, among others.

Chemical Composition

For carbon and alloy steel pipes, NACE MR0175 has limits for content Sulfur (S ≤ 0.002%), Phosphorus (P ≤ 0.020%) and Carbon (C ≤ 0.10%).

Cost of NACE MR0175 compared to General pipe

The price for NACE pipe itself is not too much higher than general steel pipe, (Especially for API 5L pipe or ASTM A106 pipe, the price is higher but not more than 100 dollars).

On the other hand, the HIC and SSC test fees are both expensive and challenging. If the required quantity is small and there is no existing stock available, it can be impossible to obtain the necessary material.

NACE MR 0175 steel pipes

API 5L: API 5L B NACE MR0175, API 5L X42/X46/X52/X56/X60/X65/X70 PSL2 NACE MR0175, API 5L LSAW NACE MR0175 steel pipes.

API 5L NACE MR0175 is suitable for piping systems for oil and gas extraction, production and transport in environments containing hydrogen sulphide. These environments can lead to corrosion, cracking, or failure of materials and require special material selection and handling.

API 5L NACE MR0175 specifies requirements for the chemical composition of pipeline materials, resistance to stress corrosion cracking (SSC) and hydrogen-induced cracking (HIC) of sulphides, as well as hardness, macro- and microstructural requirements. These requirements are intended to ensure that piping materials have good corrosion resistance and resistance to environmental stress corrosion cracking in H2S-containing environments.

LONGMA produce and export API 5L NACE MR0175 steel pipes, size from NPS2 to NPS 56, Sch10-XXS. As one of China leading steel pipes manufacturers since 2003, certified by API 5L, ISO9001, ISO14001, FPC, LONGMA always supply high quality API 5L PSL2 NACE pipes with full range pipe grades & pipe specifications. Contact by info@ilongma.com to get more information.