Analysis of National Standards Corresponding to EN 10219-1 & 2

Overview of EN 10219-1 & 2 Standards

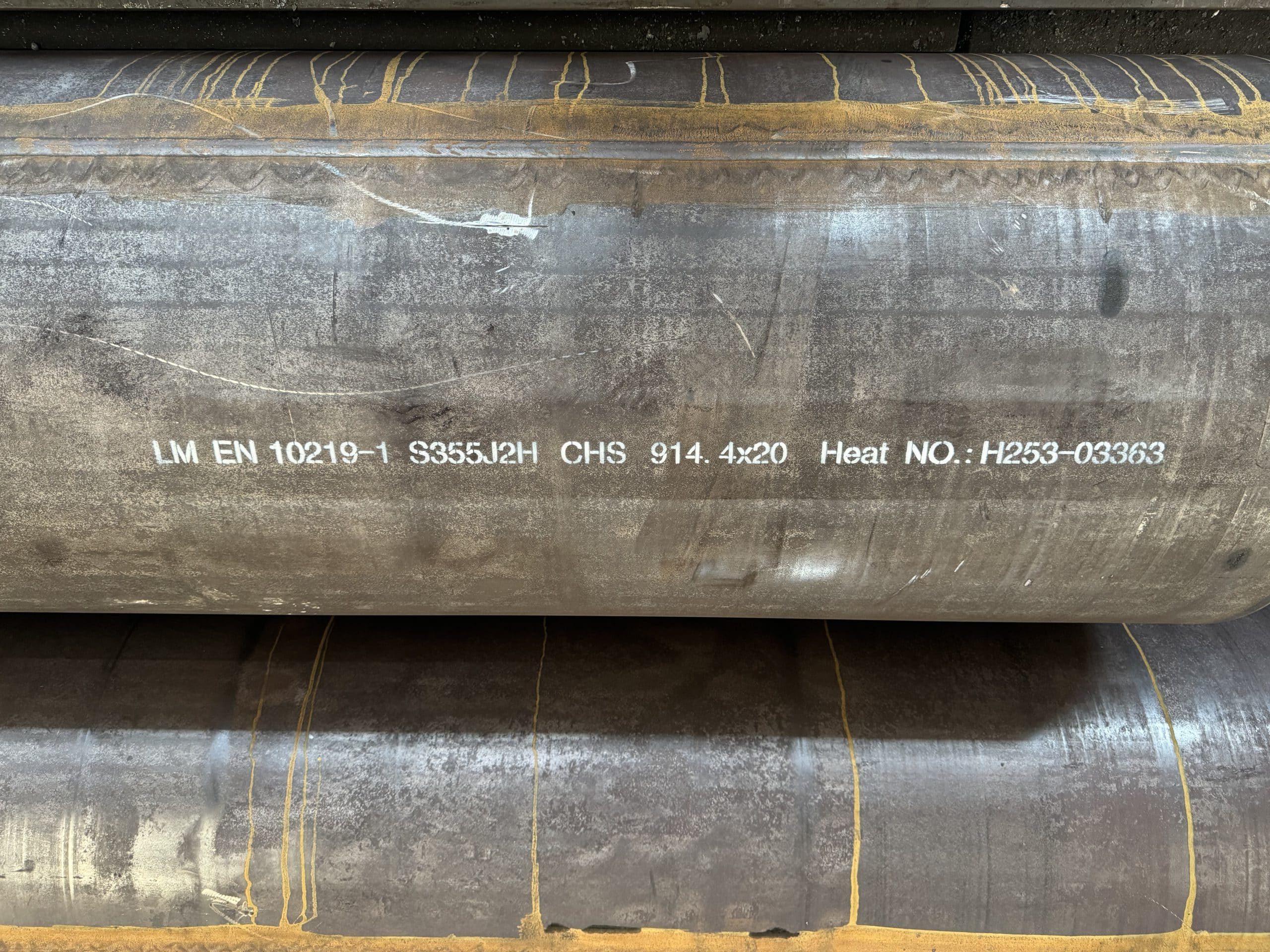

The EN 10219 series standards (including EN 10219 2006, BS EN 10219-1 2006, BS EN 10219 2 2006, and EN 10219 2 2006) apply to welded square tubes, rectangular tubes, and other cold-formed hollow section products made of non-alloy steel and fine-grained structural steel. These products are widely used in fields such as steel structures, support components, bridges, and machinery manufacturing. Among them, EN 10219 S235 (such as S235JRH EN 10219) and EN 10219 S355 (such as S355J2H EN 10219) are the most widely used steel grades in this standard. With excellent comprehensive performance, they have become common materials in global structural engineering. For domestic practitioners in related industries, understanding the corresponding national standards is of great significance for international trade and engineering construction.

Corresponding National Standards

In China, the EN 10219 standards mainly correspond to the following national standards:

| EN Standard | Corresponding National Standard | Standard Name |

| EN 10219-1 (including bs en 10219 1 2006) | GB/T 1591-2018 | 《Low Alloy High Strength Structural Steel》 |

| EN 10219-2 (including en 10219 2 2006, bs en 10219 2 2006) | GB/T 6728-2017 | 《Cold-formed Thin-walled Steel Structures Welded Square and Rectangular Steel Tubes – Dimensions, Shape, Weight and Allowable Deviations》 |

In terms of the scope of application, the steel part of EN 10219-1 is mainly regulated by GB/T 1591 in China, covering similar steel grades and mechanical properties. The dimensional tolerances and appearance requirements are stipulated by GB/T 6728.

Comparison of Steel Grades and Raw Material Standards

Common structural steel grades in EN 10219-1 are as follows:

- en 10219 s235jrh (s235jrh en 10219)

- S275J2H

- en 10219 s355j2h (s355j2h en 10219)

- S355NH

- S420MH, etc.

These steel grades have good weldability, toughness, and strength, and are suitable for high-load structures. The corresponding steel grades in China’s GB/T 1591 standard mainly include:

- Q235B/Q235C

- Q275B/Q275D

- Q355B/Q355D/Q355E

- Q460C/Q460E

Among them, S355J2H EN 10219-1 ≈ Q355D is one of the most common benchmark combinations, with similar yield strength (≥355MPa) and low-temperature impact performance. However, it should be noted that the chemical composition and test methods of the two systems are not completely consistent. Therefore, direct substitution is not recommended in important projects, and feasibility should be confirmed through performance comparison or third-party certification.

Impact Energy Requirements for Various Steel Grades in EN 10219-1 and GB/T1591

| EN 10219-1 Steel Grade | Test Temperature (℃) | Impact Energy Requirement (J) | Corresponding Steel Grade in GB/T 1591 | Test Temperature (℃) | Impact Energy Requirement (J) |

| s235jrh en 10219 | 20 | ≥27 | Q235B | 20 | ≥27 |

| S275J2H | -20 | ≥27 | Q275D | -20 | ≥34 |

| s355j2h of 10219 | -20 | ≥27 | Q355D | -20 | ≥34 |

| S355NH | -40 | ≥34 | Q355E | -40 | ≥34 |

| S420MH | -50 | ≥47 | Q460E | -40 | ≥34 |

Note: The impact energy test of EN standards mainly uses Charpy V-notch specimens. Except for specific steel grades, the GB/T 1591 standard is also based on the Charpy V-notch test, but the impact energy indicators of some steel grades are slightly adjusted due to different application scenarios.

Application Fields and Uses

EN 10219 series steel pipes (especially EN 10219-1 S235 and EN 10219-1 S355 steel grades) are suitable for the following scenarios:

- Steel structure construction: such as factories, office buildings, airport terminals, etc.

- Bridge structures: especially a large number of square and rectangular pipes are used in truss bridges and arch bridges.

- Machinery and equipment frames: meeting the requirements of high-strength and lightweight structures.

- Transportation facilities: highway guardrails, signposts, tunnel supports, etc.

- Photovoltaic brackets and wind power tower structures.

GB/T 6728 is also widely used in the above fields and is an important standard for domestic steel structure design and manufacturing.

- Domestic and Foreign Application Cases

- Foreign Cases

- Berlin Central Station, Germany: A large number of S355J2H EN 10219 square pipes meeting the requirements of BS EN 10219 1 2006 are used. These are used as roof structures and column supports, with an impact energy of 32J at -20℃, meeting the structural safety requirements in severe cold weather.

- Container frame facilities at the Port of Rotterdam, the Netherlands: S420MH high-strength hollow steel compliant with EN 10219 2006 is used to provide stronger load-bearing performance while reducing the structural weight.

- UK Crossrail urban railway project: Cold-formed hollow rectangular pipes meeting the dimensional standards of EN 10219 2 2006 are used to improve construction accuracy and connection efficiency.

- Domestic Cases

- Shenzhen World Expo Convention Center: Q355D square and rectangular tubes (equivalent to S355J2H EN 10219) compliant with GB/T 6728 are used as spatial truss nodes and main structural support tubes, meeting strength and appearance requirements.

- Transportation facilities on the artificial island of the Hong Kong-Zhuhai-Macau Bridge: Some components adopt cold-formed structural tubes equivalent to EN 10219 2006, and performance consistency is ensured through third-party certification. The guardrails made of S235JRH EN 10219 material performed excellently in impact resistance tests.

- Multiple photovoltaic bracket projects of State Power Investment Corporation (2020-2023): Q355B structural square tubes (based on S355J2H) compliant with GB/T 6728 are used. These square tubes have the characteristics of light weight and high strength, effectively improving construction efficiency and saving costs.

Summary and Recommendations

EN 10219-1 and EN 10219-2 (including BS EN 10219 1 2006 and BS EN 10219 2 2006) are EU standards for cold-formed structural tubes. In China, reference can be made to GB/T 1591-2018 and GB/T 6728-2017 respectively.

Although they are extremely similar in application fields and performance requirements, there are certain differences in material composition, test standards, and certification systems. In projects involving major steel grades such as EN 10219 S235JRH and EN 10219 S355J2H, special attention should be paid to the matching of impact energy, welding processes, and other indicators to avoid risks caused by direct substitution. Only through accurate benchmarking and performance verification can the safety and reliability of materials in international projects be ensured.

LONGMA produces and stocks a full range of EN 10219-1 Cold Finished Structural Hollow Section(CHS). It can be welded or seamless heavy wall steel pipes for machine work. We export tens of thousands of tons of such steel pipes every year to EU, UK, Thailand, Singapore, Austrilia, New Zealand, Iran, Peru, Chile. If you want to import high quality EN10219 S235/S355 steel pipes, come to LONGMA.

*Grades: S235/S355 JRH/J0H/J2H

*Outer Diameter: 4″-56″

*Thickness: 0.237″-5.90″

*Surface Treatment: Natural, Varnished, Black painting, FBE, 3PE (3LPE), 3PP, FBE, HDG(Hot Dipped Galvanized)

Email: info@ilongma.com

Reference:

Artical:

Standard: